International Conference

Welding and Related Technologies

– Present and Future

25-26 November, 2013

Kyiv, Ukraine

The International Conference «Welding and Related Technologies – Present and Future». will be held by the E.O. Paton Electric Welding Institute of the National Academy of Sciences of Ukraine on 25-26 November, 2013 in Kyiv.

The invited papers of scientists from different countries of the world about the most important research achievements, obtained during recent years in the field of welding, surfacing, brazing, strength, new materials, NDT and technical diagnostics, evaluation of residual life of welded structures, surface engineering, special electrometallurgy, as well as prospects of progress of these trends will be presented and discussed at the plenary sessions of the Conference. Alongside with plenary sessions the poster papers will be also presented.

INTERNATIONAL PROGRAM COMMITTEE

( Click to view / hide)- B. Paton, Ukraine — Chairman

- N. Alyoshin, Russia

- M. Beloev, Bulgaria

- P. Wullin, Great Britain

- E. Gdoutos, Greece

- I. Gorynin, Russia

- I. Hrivnak, Slovakia

- G. Grigorenko, Ukraine

- Guan Qiao, China

- L. Denisov, Belarus

- D. Dehelean, Romania

- T. Debroy, USA

- U. Dilthey, Germany

- A. Jardy, France

- A. Zubchenko, Russia

- E. Kablov , Russia

- S. Keitel, Germany

- Qiu Xianyang, China

- P. Klamo, Slovakia

- Ja. Kleiman, Canada

- G. Knyshov, Ukraine

- M. Kocak, Turkey

- I. Krivtsun, Ukraine

- S. Kuchuk-Yatsenko, Ukraine

- V. Lysak, Russia

- M. Lebedev, Russia

- L. Lobanov , Ukraine

- K. Middeldorf, Germany

- T. Miyata, Japan

- B. Movchan, Ukraine

- V. Naidek, Ukraine

- Z. Nazarchuk, Ukraine

- N. Novikov, Ukraine

- Yu. Okamoto, Japan

- V. Panasyuk, Ukraine

- J. Pilarczyk, Poland

- Yu. Pleskachevsky, Belarus

- I. Pokhodnya, Ukraine

- U. Reisgen, Germany

- A. Scotti, Brazil

- V. Skorokhod, Ukraine

- K. Smallbone, Australia

- Ch. Sommitsch, Austria

- G. Tavadze, Georgia

- D. von Hofe, Germany,

- J. Huete, Spain

- K. Yushchenko, Ukraine

VENUE

REGISTRATION

The registration of the Conference participants will take place at the lobby of the E.O. Paton Electric Welding Institute (building No.4) on November 24 from 8.30 am to 6.00 pm and on November 25 from 8.00 am to 10.00 am.CONFERENCE SCHEDULE

November 25, 2013 — Opening of the Conference and plenary session10.00-18.00

November 26, 2013 — Plenary session 9.00-13.00

November 26, 2013 — Poster session. 14.00-17.00.

Closing of the Conference.

CONFERENCE FEE

Registration fee is 350 US dollars (or 280 Euro).The registration fee includes: the expenses for publication of Proceedings of plenary session papers, reception, banquet, coffee and tea breaks and others.

The registration fee should be transferred to the following banks:

( Click to view / hide the bank details)

For US dollars

Beneficiary

E.O. Paton Electric Welding Institute, OKPO 5416923

11, Bozhenko Street, 03150, Kiev, Ukraine

Acc. 25300010010/840 in «Ukreximbank», 127 Gorky Street, Kiev

MFO 322313 SWIFT: EXBSUAUX

Correspondent Bank

JP Morgan Chase Bank N.A., New York, USA

Acc.400-124432, SWIFT CHAS US 33

Deutsche Bank Trust Company, USA

Acc. 04094227, SWIFT: BKTR US 33

Citibank N.A., New York, USA

Acc. 36083522, SWIFT: CITI US 33

For EUR

Beneficiary

E.O. Paton Electric Welding Institute, OKPO 5416923

11, Bozhenko Street, 03150, Kiev, Ukraine

Acc. 25300010010/978 in «Ukreximbank», 127 Gorky Street, Kiev

MFO 322313 SWIFT: EXBSUAUX

Correspondent Bank

Deutsche Bank AG, Frankfurt am Main, Germany

Acc. 9498767 10, SWIFT: DEUT DE FF

Commerzbank AG, Frankfurt am Main, Germany

Acc. 400 886636000, SWIFT: COBA DE FF

Beneficiary

E.O. Paton Electric Welding Institute, OKPO 5416923

11, Bozhenko Street, 03150, Kiev, Ukraine

Acc. 25300010010/840 in «Ukreximbank», 127 Gorky Street, Kiev

MFO 322313 SWIFT: EXBSUAUX

Correspondent Bank

JP Morgan Chase Bank N.A., New York, USA

Acc.400-124432, SWIFT CHAS US 33

Deutsche Bank Trust Company, USA

Acc. 04094227, SWIFT: BKTR US 33

Citibank N.A., New York, USA

Acc. 36083522, SWIFT: CITI US 33

For EUR

Beneficiary

E.O. Paton Electric Welding Institute, OKPO 5416923

11, Bozhenko Street, 03150, Kiev, Ukraine

Acc. 25300010010/978 in «Ukreximbank», 127 Gorky Street, Kiev

MFO 322313 SWIFT: EXBSUAUX

Correspondent Bank

Deutsche Bank AG, Frankfurt am Main, Germany

Acc. 9498767 10, SWIFT: DEUT DE FF

Commerzbank AG, Frankfurt am Main, Germany

Acc. 400 886636000, SWIFT: COBA DE FF

After transfer of the registration fee, please, inform the name of a participant and the date and number of payment order to A.V.Babaev, the Secretary of the Organizing Committee, by Fax or E-mail.

The fee can also be paid during registration.

VISAS

To obtain visa, You will need an official invitation. We kindly ask You to fill the enclosed registration form, indicating Your name, date of birth and passport number, and we will send You the official letter of invitation on the grounds of whichYou can get Your entry visa to Ukraine at the Embassy of Ukraine in Your country.

(EU countries, USA, Canada, South Korea, Brazil, Japan, Turkey, Serbia,

Montenegro, Macedonia do not need visa).

HOTELS

The central hotels of the city are offered to the Conference participants:( Click to view / hide the hotels details)

«PREMIER-PALACE»

5-7/29 T. Shevchenko blvd.,

Tel.: (380 44) 537 45 00, 537 45 01

Fax: (380 44) 279 87 72

e-mail: reservation@premier-palace.com

Single room with breakfast is 325 – 475 Euro;

Double room with breakfast is 395-545 Euro.

«RUS»

4, Gospitalnaya str.,

Tel.: (380 44) 256 40 00

Fax: (380 44) 289 43 96

e-mail: reservation@hotelrus.kiev.ua

Single room with breakfast is 900-1950 UAH;

Double room with breakfast is 1020-1390 UAH.

«DNIPRO«

1/2, Kreshchatik str.,

Tel.: (380 44) 254 67 77

Fax: (380 44) 254 67 75

e-mail: reservation@dniprohoTel.:ua

Single room with breakfast, depending on class is 73-160 Euro;

Double room with breakfast is 89 – 210 Euro.

«KRESHCHATIK«

14, Kreshchatik str.,

Tel.: (380 44) 596 80 00

Fax: (380 44) 596 80 01

e-mail: reservation@hotel-khreschatyk.ua

Single room of «prestige» class with breakfast is 1900 UAH;

«UKRAINA»

4, Institutskaya str.,

Tel.: (380 44) 278 28 04; 278 66 75

Fax: (380 44) 279 13 53;

e-mail: reservation@ukraine-hoTel.:kiev.ua

Single room (depending on class) with breakfast is 750 – 1100 UAH;

Double room (depending on class) with breakfast is 500-625 UAH.

Prices are indicated per one place without reservation.

«PRESIDENT HOTEL-KYIV»

12, Hospitalnaya str.,

Tel.: (38044) 256 38 56

Fax (38044) 256 32 53

e-mail: reservation@ president-hoTel.:com.ua

Single room with breakfast is 182 – 402 Euro;

Double room with breakfast is 204 – 424 Euro.

HC «FEOFANIYA» of the NASU

6/11, S.Perovskaya str.,

Tel.: (38 044) 456 64 53

Fax: (38 044) 371 64 48

e-mail: manager@feofaniya.org.ua

Two-bed suite is 260-300 UAH;

Single-bed suite is 350 UAH;

Suite of the II category is 250 UAH.

The prices indicated are valid as per June, 2013.

Currency exchange rate as per June, 2013:

1 US dollar is 8.1 UAH ( Hryvna of Ukraine);

1 Euro is 10.2 UAH

The Organizing Committee will appreciate if You send until 25 October, 2013

the name of hotel, which You reserved yourself or desire to reserve and the

period of stay. Contact the telephone: (38044) 200-60-16.

5-7/29 T. Shevchenko blvd.,

Tel.: (380 44) 537 45 00, 537 45 01

Fax: (380 44) 279 87 72

e-mail: reservation@premier-palace.com

Single room with breakfast is 325 – 475 Euro;

Double room with breakfast is 395-545 Euro.

«RUS»

4, Gospitalnaya str.,

Tel.: (380 44) 256 40 00

Fax: (380 44) 289 43 96

e-mail: reservation@hotelrus.kiev.ua

Single room with breakfast is 900-1950 UAH;

Double room with breakfast is 1020-1390 UAH.

«DNIPRO«

1/2, Kreshchatik str.,

Tel.: (380 44) 254 67 77

Fax: (380 44) 254 67 75

e-mail: reservation@dniprohoTel.:ua

Single room with breakfast, depending on class is 73-160 Euro;

Double room with breakfast is 89 – 210 Euro.

«KRESHCHATIK«

14, Kreshchatik str.,

Tel.: (380 44) 596 80 00

Fax: (380 44) 596 80 01

e-mail: reservation@hotel-khreschatyk.ua

Single room of «prestige» class with breakfast is 1900 UAH;

«UKRAINA»

4, Institutskaya str.,

Tel.: (380 44) 278 28 04; 278 66 75

Fax: (380 44) 279 13 53;

e-mail: reservation@ukraine-hoTel.:kiev.ua

Single room (depending on class) with breakfast is 750 – 1100 UAH;

Double room (depending on class) with breakfast is 500-625 UAH.

Prices are indicated per one place without reservation.

«PRESIDENT HOTEL-KYIV»

12, Hospitalnaya str.,

Tel.: (38044) 256 38 56

Fax (38044) 256 32 53

e-mail: reservation@ president-hoTel.:com.ua

Single room with breakfast is 182 – 402 Euro;

Double room with breakfast is 204 – 424 Euro.

HC «FEOFANIYA» of the NASU

6/11, S.Perovskaya str.,

Tel.: (38 044) 456 64 53

Fax: (38 044) 371 64 48

e-mail: manager@feofaniya.org.ua

Two-bed suite is 260-300 UAH;

Single-bed suite is 350 UAH;

Suite of the II category is 250 UAH.

The prices indicated are valid as per June, 2013.

Currency exchange rate as per June, 2013:

1 US dollar is 8.1 UAH ( Hryvna of Ukraine);

1 Euro is 10.2 UAH

TRANSPORT

The Conference participants will be provided with transport for meeting and departure (if necessary), and also during the period of the Conference.

TIME, CLIMATE

Local time is one hour ahead of the European time. Kyiv climate is continental.

Average temperature in November is 0 – minus 10 °C.

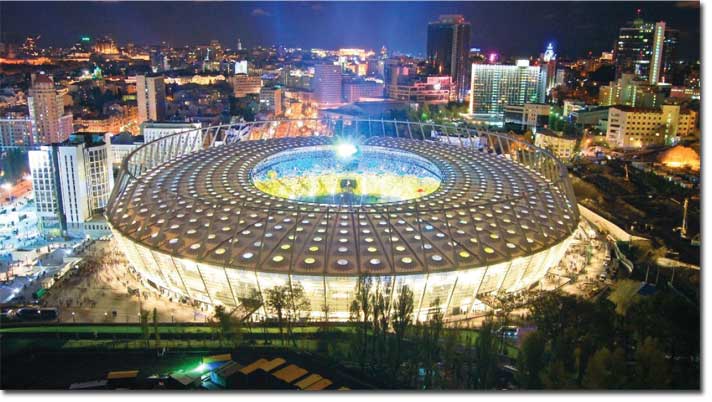

INFORMATION ABOUT KYIV

( Click to view / hide the information about Kyiv)

Kyiv, the capital of a sovereign state of Ukraine, is one of the most ancient

cities in the world. It was founded in the V century and is known in the history

as «mother of Russian cities», the capital of the first Eastern-Slavonic state,

the Kievan Rus. Kyiv played an important role in the development of the world

culture. It is from here that Christianity, adopted by Prince Vladimir in 988, started

spreading in Russia.

Today Kyiv is developing as an European capital, city of tourism, industry and science. Having a population of about 3 million, Kyiv is the political, cultural, sport and industrial center of modern Ukraine. Here, the National Academy of Sciences of Ukraine, dozens of research institutes, design organizations and institutions of higher education are located. Industries involved are electronics, machine-building and aircraft engineering, metal working, food processing, chemical and petrochemical production and many others. Kyiv has a lot to offer to any visitor. It is famous for many architectural monuments. Very popular among residents of Kyiv and visitors are the National Opera House, circus, the Ukrainian Fork Choir and Dance companies, museums.

More than 60 % of Kyiv area is covered with gardens, parks and tree-lined boulevards. Kyiv is located on the banks of the Dnieper river, this making it inimitable in its charm.

Today Kyiv is developing as an European capital, city of tourism, industry and science. Having a population of about 3 million, Kyiv is the political, cultural, sport and industrial center of modern Ukraine. Here, the National Academy of Sciences of Ukraine, dozens of research institutes, design organizations and institutions of higher education are located. Industries involved are electronics, machine-building and aircraft engineering, metal working, food processing, chemical and petrochemical production and many others. Kyiv has a lot to offer to any visitor. It is famous for many architectural monuments. Very popular among residents of Kyiv and visitors are the National Opera House, circus, the Ukrainian Fork Choir and Dance companies, museums.

More than 60 % of Kyiv area is covered with gardens, parks and tree-lined boulevards. Kyiv is located on the banks of the Dnieper river, this making it inimitable in its charm.

SOCIAL EVENTS

Visit to theatres, circus, and concerts will be offered at choice.Banquet: (Tuesday, Nov. 26, 18.00 It will be held at the Guest Hall (build. 1, 2nd floor).

Presentation of plenary papers

To present the plenary paper, 20 minutes will be given. Demonstration of plenary papers will be provided using the multimedia projector.Presentation of poster papers

Poster papers will be systematized by scientific directions and arranged in a reading hall of the Institute library (build. 4, 2nd floor). Requirements for preparation of poster papers are as follows:- poster papers should be arranged on one or two boards of size:

- A1 - 90 cm (height) x 60 cm (width);

- at the top the names of authors and topic of the paper should be written by letters of 30 mm height;

- below, the scientific information is arranged.

WORKING ORGANIZING COMMITTEE

Chairman — Prof. Lobanov LeonidTel.: (380 44) 200-24-55

Scientific Secretary— Dr. Babaev Alexander

Tel.: (380 44) 200-61-70

Members of the Organizing Committee:

Prof. Kireev Leonid Tel.: (380 44) 200-47-83

Dr. Zelnichenko Alexander Tel.: (380 44) 200-82-77

Lokteva Veronika Tel./Fax: (38 044) 206-17-87

Tel.: (380 44) 200-60-16

Address:

The E.O. Paton Electric Welding Institute

11, Bozhenko str., Kyiv, 03680, Ukraine

Fax: (380 44) 528 04 86

E-mail: office@paton.kiev.ua

www.patonpublishinghouse.com

PROGRAM OF THE CONFERENCE

November 25, 2013PLENARY SESSION

Conference-Hall, build.4, 2nd floor

10.00

Opening of the Conference

( Click to view / hide the list of reports)

1. Research and developments of the E.O. Paton Electric Welding Institute

for the nowadays power engineering. Prof. B.E. Paton (Ukraine)

2. Strategic trends of development of structural materials and technologies of their processing for aerospace engineering objects. Prof. E.N. Kablov, O.G. Ospennikov, Dr. B.S. Lomberg (Russia)

3. Progress in non-conventional welding and related processes at Beijing Aeronautical Manufacturing Technology Research Institute. Prof. Qiao Guan (China)

4. Welding or Adhesive Bonding – is this a question for the future? Prof. U. Reisgen, M. Schleser (Germany)

5. Recent advances in the quantitative understanding of friction welding. Prof. DebRoy and A. De (USA)

6. Innovation technologies in the field of structural steels and welding. Prof. I.V. Gorynin (Russia)

7. Trends in developments in gas-shielded arc welding equipment in Japan. Prof. T. Ueyama (Japan)

8. Welding today and tomorrow. Prof. J. Pilarczyk , W. Zeman (Poland)

2. Strategic trends of development of structural materials and technologies of their processing for aerospace engineering objects. Prof. E.N. Kablov, O.G. Ospennikov, Dr. B.S. Lomberg (Russia)

3. Progress in non-conventional welding and related processes at Beijing Aeronautical Manufacturing Technology Research Institute. Prof. Qiao Guan (China)

4. Welding or Adhesive Bonding – is this a question for the future? Prof. U. Reisgen, M. Schleser (Germany)

5. Recent advances in the quantitative understanding of friction welding. Prof. DebRoy and A. De (USA)

6. Innovation technologies in the field of structural steels and welding. Prof. I.V. Gorynin (Russia)

7. Trends in developments in gas-shielded arc welding equipment in Japan. Prof. T. Ueyama (Japan)

8. Welding today and tomorrow. Prof. J. Pilarczyk , W. Zeman (Poland)

Break 14.00-15.00

( Click to view / hide the list of reports)

9. Advanced informative automated systems of acoustic control of welding.

Prof. N.P. Alyoshin (Russia)

10. Fundamentals of technology of electric contact sintering of nanostructured metal-polymeric coatings of tribotechnical purpose.Prof. Yu. Pleskachevsky, Prof. V.A. Kovtun (Belarus)

11. Non-invasive condition monitoring of storage tank. Prof. Tat-Hean Gan, Vixhaar Dimlaye, Peter Mudge, Paul Jackson and Slim Soua (Great Britain)

12. Numerical simulation and experimental investigation of remelting process. Dr. A. Jardy (France)

13. Tends in welding in Austria. Prof. Ch. Sommitsch and Norbert Enzinger (Austria)

14. Ongoing activities and prospects related to welding technology at Laprosolda- Brazil. Prof. Louriel Vilarinho and Laura Vilarinho (Brazil)

15. Micro-welding of aluminium alloy by superposition of pulsed Nd:YAG laser and continuous diode laser. Dr. Y. Okamoto, S. Nakashiba, T. Sakagawa and A.Okada (Japan)

16. Technology of hybrid laser welding for main pipelines. Prof. S. Keitel (Germany)

17. Mechanical behavior and future of sandwich structures. Prof. E. Gdoutos (Greece)

10. Fundamentals of technology of electric contact sintering of nanostructured metal-polymeric coatings of tribotechnical purpose.Prof. Yu. Pleskachevsky, Prof. V.A. Kovtun (Belarus)

11. Non-invasive condition monitoring of storage tank. Prof. Tat-Hean Gan, Vixhaar Dimlaye, Peter Mudge, Paul Jackson and Slim Soua (Great Britain)

12. Numerical simulation and experimental investigation of remelting process. Dr. A. Jardy (France)

13. Tends in welding in Austria. Prof. Ch. Sommitsch and Norbert Enzinger (Austria)

14. Ongoing activities and prospects related to welding technology at Laprosolda- Brazil. Prof. Louriel Vilarinho and Laura Vilarinho (Brazil)

15. Micro-welding of aluminium alloy by superposition of pulsed Nd:YAG laser and continuous diode laser. Dr. Y. Okamoto, S. Nakashiba, T. Sakagawa and A.Okada (Japan)

16. Technology of hybrid laser welding for main pipelines. Prof. S. Keitel (Germany)

17. Mechanical behavior and future of sandwich structures. Prof. E. Gdoutos (Greece)

November 26, 2013

Conference-Hall, build.4, 2nd floor9.00

( Click to view / hide the list of reports)

18. Plasma processes in metallurgy and technology of inorganic materials.

Prof. Yu.V. Tsvetkov, A.V. Nikolaev, A.V. Samokhina (Russia)

19. Gas-shielded arc welding of aluminium light weight structures. Prof. R. Winkler (Germany)

20. Application of explosion energy in welding, related processes and technologies. Prof. V.I. Lysak (Russian)

21. Trends in joining technologies – value added by welding technology. Dr. K. Middeldorf (Germany)

22. Challenging technologies of manufacture of highly-reliable structures of structural steels for basic branches of industry. Prof. A. Dub (Russia)

23. Analysis and selection of welding technologies in construction of largediameter main pipelines. Dr. M. Beloev (Bulgaria), V.I. Khomenko, Prof. S.I. Kuchuk-Yatsenko( Russia, Ukraine)

24. Residual stress management in welding: measurement, fatigue analysis and improvement treatments. Dr. Yu. Kudryavtsev, Prof. J. Kleiman, (Canada)

25. Advances in pipeline welding technologies and weld joint properties. Prof. M. Kocak (Turkey)

26. Welding, cutting and heat treatment of live tissues. Prof. B.E. Paton, Prof. I.V. Krivtsun, Dr. G.S. Marinsky, Dr. I.Yu. Khudetsky, Dr. Yu.N. Lankin, Dr. A.V. Chernets (Ukraine)

19. Gas-shielded arc welding of aluminium light weight structures. Prof. R. Winkler (Germany)

20. Application of explosion energy in welding, related processes and technologies. Prof. V.I. Lysak (Russian)

21. Trends in joining technologies – value added by welding technology. Dr. K. Middeldorf (Germany)

22. Challenging technologies of manufacture of highly-reliable structures of structural steels for basic branches of industry. Prof. A. Dub (Russia)

23. Analysis and selection of welding technologies in construction of largediameter main pipelines. Dr. M. Beloev (Bulgaria), V.I. Khomenko, Prof. S.I. Kuchuk-Yatsenko( Russia, Ukraine)

24. Residual stress management in welding: measurement, fatigue analysis and improvement treatments. Dr. Yu. Kudryavtsev, Prof. J. Kleiman, (Canada)

25. Advances in pipeline welding technologies and weld joint properties. Prof. M. Kocak (Turkey)

26. Welding, cutting and heat treatment of live tissues. Prof. B.E. Paton, Prof. I.V. Krivtsun, Dr. G.S. Marinsky, Dr. I.Yu. Khudetsky, Dr. Yu.N. Lankin, Dr. A.V. Chernets (Ukraine)

November 26, 2013

POSTER SESSION

Reading Hall of library, build.4, 2nd floor14.00

1. TECHNOLOGY,MATERIALS AND EQUIPMENT FOR WELDING AND RELATED TECHNOLOGIES ( Click to view / hide the list of reports)

1.1. V.V. Bashenko, K.A. Okhapkin. Effect of main design-technological parameters of spot friction welding on volumetric interaction proceeding (Russia)

1.2. V.Yu. Belous, S.V. Akhonin, R.V. Selin, S.L. Antonyuk. Welding of highstrength titanium alloy T110 (Ukraine)

1.3. S.V. Bondarev. Investigation of hydrophobic-hydrophilic properties of electrode covering components (Ukraine)

1.4. S. Brumm, G. Buerkner, M. Kusch. Welding of unalloyed steels with GMAW process using thick wire electodes (Germany)

1.5. A.V. Vladimirov, V.A. Khabuzov, S.Yu. Maksimov, V.A. Lebedev. Digital synthesis of pulsed arc welding (Russia, Ukraine)

1.6. P.A. Gavrish, V.I. Tulupov. Improvement of preheating methods for copper to steel welding (Ukraine)

1.7. A.A. Gaivoronsky, Yu.V. Demchenko, A.I. Panfilov. Technologies for welding repair of damaged members of metal structures of ore mining and processing equipment (Ukraine)

1.8. V.V. Golovko, I.K. Pokhodnya. Effect of morphology of non-metallic inclusions on formation of microstructure of the weld metal on high-strength low-alloy steels (Ukraine)

1.9. I.A. Goncharov. Development of welding fluxes with predictable technological and metallurgical properties on the basis of structural and physical- chemical investigations (Ukraine)

1.10. S.N. Goncharov, M.P. Shalimov. Selection of procedures for evaluation of weldability of high-strength steels (Russia)

1.11. E.G. Grigorieva, D.A. Chinakhov. Possibility of using welding with double- jet gas shielding for repair of worn-out surfaces of parts (Russia)

1.12. B.A. Grinberg, M.A. Ivanov, V.V. Rybin, A.M. Patselov, Yu.P. Besshaposhnikov. Explosion welding: processes and structures (Russia)

1.13. A.G. Grin, I.A. Boiko. Procedure for determination of composition of fluxcored wire (Ukraine)

1.14. A.G. Grin, T.B. Zolotopupova. Gas-shielded arc welding of aluminised steel (Ukraine)

1.15. A.A. Demyanchenko. Control of structure of zones of welded joints on alloyed steels by using the adaptive pulsed technologies of welding (Russia)

1.16. V.P. Elagin, G.N. Gordan. On the mechanism of decreasing chemical and structural heterogeneity in the austenitic weld to low-carbon steel fusion zone (Ukraine)

1.17. D.I. Zainulin, V.A. Lebedev, S.V. Maksimov, V.G. Pichak. Unique system of equipment for automatic arc welding at large depths under the maximum limited conditions (Ukraine)

1.18. L.S. Zakharov, A.R. Gavrik. Development of the technology for welding of dissimilar joints on martensitic steel 10KH9NMFB to austenitic chrome-nickel steels of the 08KH18N10T type ( Ukraine)

1.19. V.M. Ilyushenko, V.A. Anoshin, A.N. Bondarenko, T.B. Maidanchuk, N.V. Skorina. Development of electrode materials for welding and cladding of multi-component bronzes (Ukraine)

1.20. V.M. Ilyushenko, A.V. Ganchuk, V.A. Lysenko, V.N. Petrichenko, D.N. Stepchenko High-efficiency technology for welding of thick metal (Ukraine)

1.21. S.V. Kabysh, G.B. Esaulenko, M.G. Menzheres. Peculiarities of formation of supermolecular structure of the joining zone in ultrasonic and thermal welding of crystalline polymeric sheets (Ukraine)

1.22. V.D. Kassov, A.M. Kushchij. Upgrading of the technology for surface preparation of metal structures of a complex volume-surface shape for repair welding (Ukraine)

1.23. V.V. Kvasnitsky, A.M. Kostin, A.V. Labartkava, Al.V. Labartkava. Peculiarities of brazing of cermet pressure seals (Ukraine)

1.24. V.V. Kvasnitsky, L.I. Markashova, V.F. Kvasnitsky, N.N. Koval, Yu.F. Ivanov, V.V. Uglov, N.N. Cherenda, I.L. Levchenko. Diffusion bonding of metals using radiation-beam technologies (Ukraine, Russia, Belarus)

1.25. V.V. Kvasnitsky, L.I. Markashova, V.F. Kvasnitsky, N.N. Koval, Yu.F. Ivanov, V.V. Uglov, N.N. Cherenda, I.L. Levchenko. Brazing of metals using radiation-beam technologies (Ukraine, Russia, Belarus)

1.26. A.E. Korotynsky. Investigation of self-adjustment processes in resonance arc welding (Ukraine)

1.27. A.E. Korotynsky, I.V. Vertetskaya, V.A. Shapka. Application of differential taylor transform in problems of investigation of processes occurring in nonlinear oscillatory circuit (Ukraine)

1.28. A.E. Korotynsky, N.P. Drachenko, V.A. Shapka. Peculiarities of charging- discharging processes in super capacitors ( Ukraine)

1.29. V.M. Kulik, E.L. Demchenko, D.V. Vasiliev, V.P. Elagin. New electrode materials for welding and cladding of high-strength and dissimilar steels (Ukraine)

1.30. T.M. Labur. Increase in strength and toughness of welded joints on aluminium alloys (Ukraine)

1.31. V.A. Lebedev, A.I. Gedrovich, K.V. Borodina. Electric-arc fusion welding of metal of small thickness (Ukraine)

1.32. V.A. Lebedev, A.I. Gedrovich, V.N. Sysoev. Formation of welds in gas-shielded pulsed arc welding of beams (Ukraine)

1.33. V.A. Lebedev, S.Yu. Maksimov, I.V. Lendel. Mathematical model of temperature fields and optimal parameters of deposited bead under controlled mechanical effects (Ukraine)

1.34. V.A. Lebedev, S.Yu. Maksimov, Yu.A. Yaros. Power supply for mechanised metal arc welding of remote objects (Ukraine)

1.35. V.A. Lebedev, D.V. Plyushch. Technological reliability of mechanised welding equipment (Ukraine)

1.36. V.A. Lebedev, M.S. Sorokin, A.A. Belov. Upgrading of principles of control of electrode metal transfer in arc welding with short circuits (Ukraine, Russia)

1.37. L.M. Lobanov, O.M. Timoshenko, P.V. Goncharov Technology and equipment for arc spot welding in vertical position (Ukraine)

1.38. M.V. Matvienko, G.V. Ermolaev, V.V. Kvasnitsky. Influence of slipping of dissimilar material surfaces being joined on the stress-strain state in vacuum diffusion welding with thermal cycling (Ukraine)

1.39. P. Mayr, M. Kusch, L. Ebert, F. Podlesak. Influence of plasma transfer arc welding with pulsed process gas feeding on welding metallurgy of cobalt based hardfacing alloys (Germany)

1.40. S.I. Moravetsky, A.K. Tsaryuk, V.Yu. Skulsky. Certification of technology of welding combined rotors from steels 25Kh2NMFA + 20Kh3MVFA (EI415) for steam turbines (Ukraine)

1.41. N.P. Nesterenko, A.N. Galchun, V.Yu. Kondratenko, A.G. Skok. On effectiveness of application of pneumatically driven machine for butt welding of up to 400 mm diameter pipes from crystal-amorphous polymers (Ukraine)

1.42. N.P. Nesterenko, S.M. Dyachenko, I.K. Senchenkov. Technology and equipment for ultrasonic welding of heat-resistant composite materials applied in automotive and aircraft construction (Ukraine)

1.43. N.P. Nesterenko, N.G. Korab, A.N. Galchun. Experimental-theoretical investigation of laser welding of thin polyethylene films (Ukraine)

1.44. N.P. Nesterenko, E.A. Mineev. Features of welding pipes from unplasticized polyvinylchloride (Ukraine)

1.45. B.E. Paton, Yu.N. Saraev, V.A. Lebedev. Prospects for development and practical application of pulsed welding and surfacing technologies to improve operating reliability of critical metal structures (Ukraine, Russia)

1.46. B.E. Paton, K.A. Yushchenko, I.I. Lychko, S.A. Suprun, S.M. Kozulin, A.A. Klimenko. Investigation of the processes of formation of welded joint metal in electroslag welding with wire electrodes (Ukraine)

1.47. I.V. Pentegov, V.N. Sidorets, S.V. Rymar, A.M. Zhernosekov. Influence of modern arc power sources on the mains (Ukraine)

1.48. A.S. Pismennii, A.A. Pismennii, A.S. Prokofjev, R.S. Gubatyuk. Investigation and development of experimental technology and equipment for heat treatment of welds of railway rails (Ukraine)

1.49. A.S. Pismennii, V.V. Polukhin, Vl.V. Polukhin, R.S. Gubatyuk. Experimental technologies and equipment for seam welding and braze-welding of thin-walled pipes from high-strength steels by high-frequency currents (Ukraine)

1.50. V.B. Porokhonko, I.V. Protokovilov, A.T. Nazarchuk, D.A. Petrov, L.M. Babich. Electroslag welding of titanium alloys with pulsed electromagnetic impact (Ukraine)

1.51. H. Pokhmurska, B. Wielage, Ch.Rupprecht. Overview lecture about research trends for TS-processes (Germany)

1.52. I.K. Pokhodnya, A.V. Ignatenko, A.P. Paltsevich, V.S. Sinyuk. Hydrogen- induced cold cracks in welded joints of HSLA steels (Ukraine)

1.53. S.G. Psakhtje, K.A. Yushchenko, Yu.N. Saraev, Yu.N. Kakhovsky, V.P. Bezborodov. Establishing scientific fundamentals of development of multimodal welding consumables and pulsed technologies to produce permanent joints and fused coatings with multiscale structure for items operating in extreme north and arctic regions (Ukraine)

1.54. A.D. Razmyshlayev, M.V. Mironova, S.V. Yarmonov, P.A. Vydymysh. Improvement of effectiveness of processes of arc welding and surfacing under the impact of controlling magnetic fields (Ukraine)

1.55. M.K. Reznichenko, M.K. Kalin, K.O. Izotova. New methods of cold welding of cast iron by low-carbon materials (Ukraine)

1.56. A.P. Semyonov, I.V. Krivtsun, V.F. Demchenko. Simulation of the processes of melting and fusion of electrode metal in consumable electrode welding (Ukraine)

1.57. A.G. Sineok, A.M. Gerasimenko, V.D. Ryabokon, K.V. Ryabtsev, V.V. Brichak, S.N. Tolstyi. Modern welding technologies at enlargement and mounting of the arch metal structures of Podol bridge in Kiev (Ukraine)

1.58. A.G. Sineok, A.M. Gerasimenko, V.D. Ryabokon, K.V. Ryabtsev, A.A. Gotsulyak. Development of technologies of welding weather-resistant rolled stock of strength classes 355–500 MPa (Ukraine, Poland)

1.59. T.G. Skuba, V.A. Kolyada, V.V. Dolinenko, E.V. Shapovalov Development of simulation model of robotic multipass MIG/MAG welding for experimental investigations of the influence of schematics and modes of making the welds on stress-strain states (Ukraine)

1.60. E.G. Ternovoj, V.F. Shulym, Yu.N. Lankin. Repair of fragments of the case of internatonal space station with application of electron beam welding (Ukraine)

1.61. A.I. Ustinov, T.V. Melnichenko, Yu.V. Falchenko, L.V. Petrushinets. Electron beam methods to produce nanostructured foils and their application in welding of difficult-to-weld materials (Ukraine)

1.62. A.I. Ustinov, V.A. Telichko, S.A. Demchenkov, C. Bruckmueller, A. Hancic. EB PVD technology of producing functional quasicrystalline coatings and their properties (Ukraine, Austria, Slovenia)

1.63. G.K. Kharchenko, M.N. Rudenko, O.O. Novomlinets, M.O. Khomenko. Generation of electric potential on the surface of metal samples at self-propagating high-temperature synthesis in nanolayered foils (Ukraine)

1.64. V.F. Khorunov, S.V. Maksimova. Vacuum brazing of multilayer thinwalled structures (Ukraine).

1.65. V.F. Khorunov, Khorunov, S.V. Maksimova, V.V. Myasoed. Formation of brazed joints based on Ni3Al (Ukraine)

1.66. A.K. Tsaryuk, V.D. Ivanenko, N.I. Dunaevskaya. Repair technology for extension of service life of boilers of operating HPP power units (Ukraine)

1.67. A.K. Tsaryuk, O.G. Kasatkin, V.Yu. Skulsky, S.I. Moravetsky, A.R. Gavrik. Technology of welding from one side clad pipelines of primary coolant circuit of NPP power units (Ukraine)

1.68. D.A. Chinakhov. Investigation of the influence of shielding gas jet on heat distribution in the consumable electrode welding zone (Russia)

1.69. D.A. Chinakhov, A.V. Zuev. Consumable electrode welding with double- jet gas shielding (Russia)

1.70. V.A. Shapka. Selection of the structure of driving genereator for operation of HFMP actuator (Ukraine)

1.71. V.D. Shelyagin, V.Yu. Khaskin, A.G. Lukashenko. Laser welding of expansion bellows (Ukraine)

1.72. M.A. Sholokhov, A.M. Fiveiskii, D.S. Buzorina. Investigation of the influence of technological parameters on formation of near-wall bead in gas-shielded multipass welding (Russia)

1.73. M.A. Sholokhov, A.M. Fiveiskii, A.Yu. Melnikov. Twin-arc welding and its practical implementation (Russia)

1.74. K.A. Yushchenko, I.S. Gakh, B.A. Zaderiy, A.V. Zvyaginsteva, O.P. Karasevskaya. Metallurgical and technological issues of welding and repair of single-crystal blades from high-strength nickel alloys (Ukraine)

1.75. K.A. Yushchenko, T.N. Kushnareva, V.E. Mazurak. Results of investigation of producing high-temperature nickel alloy joints by reaction-diffusion process (Ukraine)

1.2. V.Yu. Belous, S.V. Akhonin, R.V. Selin, S.L. Antonyuk. Welding of highstrength titanium alloy T110 (Ukraine)

1.3. S.V. Bondarev. Investigation of hydrophobic-hydrophilic properties of electrode covering components (Ukraine)

1.4. S. Brumm, G. Buerkner, M. Kusch. Welding of unalloyed steels with GMAW process using thick wire electodes (Germany)

1.5. A.V. Vladimirov, V.A. Khabuzov, S.Yu. Maksimov, V.A. Lebedev. Digital synthesis of pulsed arc welding (Russia, Ukraine)

1.6. P.A. Gavrish, V.I. Tulupov. Improvement of preheating methods for copper to steel welding (Ukraine)

1.7. A.A. Gaivoronsky, Yu.V. Demchenko, A.I. Panfilov. Technologies for welding repair of damaged members of metal structures of ore mining and processing equipment (Ukraine)

1.8. V.V. Golovko, I.K. Pokhodnya. Effect of morphology of non-metallic inclusions on formation of microstructure of the weld metal on high-strength low-alloy steels (Ukraine)

1.9. I.A. Goncharov. Development of welding fluxes with predictable technological and metallurgical properties on the basis of structural and physical- chemical investigations (Ukraine)

1.10. S.N. Goncharov, M.P. Shalimov. Selection of procedures for evaluation of weldability of high-strength steels (Russia)

1.11. E.G. Grigorieva, D.A. Chinakhov. Possibility of using welding with double- jet gas shielding for repair of worn-out surfaces of parts (Russia)

1.12. B.A. Grinberg, M.A. Ivanov, V.V. Rybin, A.M. Patselov, Yu.P. Besshaposhnikov. Explosion welding: processes and structures (Russia)

1.13. A.G. Grin, I.A. Boiko. Procedure for determination of composition of fluxcored wire (Ukraine)

1.14. A.G. Grin, T.B. Zolotopupova. Gas-shielded arc welding of aluminised steel (Ukraine)

1.15. A.A. Demyanchenko. Control of structure of zones of welded joints on alloyed steels by using the adaptive pulsed technologies of welding (Russia)

1.16. V.P. Elagin, G.N. Gordan. On the mechanism of decreasing chemical and structural heterogeneity in the austenitic weld to low-carbon steel fusion zone (Ukraine)

1.17. D.I. Zainulin, V.A. Lebedev, S.V. Maksimov, V.G. Pichak. Unique system of equipment for automatic arc welding at large depths under the maximum limited conditions (Ukraine)

1.18. L.S. Zakharov, A.R. Gavrik. Development of the technology for welding of dissimilar joints on martensitic steel 10KH9NMFB to austenitic chrome-nickel steels of the 08KH18N10T type ( Ukraine)

1.19. V.M. Ilyushenko, V.A. Anoshin, A.N. Bondarenko, T.B. Maidanchuk, N.V. Skorina. Development of electrode materials for welding and cladding of multi-component bronzes (Ukraine)

1.20. V.M. Ilyushenko, A.V. Ganchuk, V.A. Lysenko, V.N. Petrichenko, D.N. Stepchenko High-efficiency technology for welding of thick metal (Ukraine)

1.21. S.V. Kabysh, G.B. Esaulenko, M.G. Menzheres. Peculiarities of formation of supermolecular structure of the joining zone in ultrasonic and thermal welding of crystalline polymeric sheets (Ukraine)

1.22. V.D. Kassov, A.M. Kushchij. Upgrading of the technology for surface preparation of metal structures of a complex volume-surface shape for repair welding (Ukraine)

1.23. V.V. Kvasnitsky, A.M. Kostin, A.V. Labartkava, Al.V. Labartkava. Peculiarities of brazing of cermet pressure seals (Ukraine)

1.24. V.V. Kvasnitsky, L.I. Markashova, V.F. Kvasnitsky, N.N. Koval, Yu.F. Ivanov, V.V. Uglov, N.N. Cherenda, I.L. Levchenko. Diffusion bonding of metals using radiation-beam technologies (Ukraine, Russia, Belarus)

1.25. V.V. Kvasnitsky, L.I. Markashova, V.F. Kvasnitsky, N.N. Koval, Yu.F. Ivanov, V.V. Uglov, N.N. Cherenda, I.L. Levchenko. Brazing of metals using radiation-beam technologies (Ukraine, Russia, Belarus)

1.26. A.E. Korotynsky. Investigation of self-adjustment processes in resonance arc welding (Ukraine)

1.27. A.E. Korotynsky, I.V. Vertetskaya, V.A. Shapka. Application of differential taylor transform in problems of investigation of processes occurring in nonlinear oscillatory circuit (Ukraine)

1.28. A.E. Korotynsky, N.P. Drachenko, V.A. Shapka. Peculiarities of charging- discharging processes in super capacitors ( Ukraine)

1.29. V.M. Kulik, E.L. Demchenko, D.V. Vasiliev, V.P. Elagin. New electrode materials for welding and cladding of high-strength and dissimilar steels (Ukraine)

1.30. T.M. Labur. Increase in strength and toughness of welded joints on aluminium alloys (Ukraine)

1.31. V.A. Lebedev, A.I. Gedrovich, K.V. Borodina. Electric-arc fusion welding of metal of small thickness (Ukraine)

1.32. V.A. Lebedev, A.I. Gedrovich, V.N. Sysoev. Formation of welds in gas-shielded pulsed arc welding of beams (Ukraine)

1.33. V.A. Lebedev, S.Yu. Maksimov, I.V. Lendel. Mathematical model of temperature fields and optimal parameters of deposited bead under controlled mechanical effects (Ukraine)

1.34. V.A. Lebedev, S.Yu. Maksimov, Yu.A. Yaros. Power supply for mechanised metal arc welding of remote objects (Ukraine)

1.35. V.A. Lebedev, D.V. Plyushch. Technological reliability of mechanised welding equipment (Ukraine)

1.36. V.A. Lebedev, M.S. Sorokin, A.A. Belov. Upgrading of principles of control of electrode metal transfer in arc welding with short circuits (Ukraine, Russia)

1.37. L.M. Lobanov, O.M. Timoshenko, P.V. Goncharov Technology and equipment for arc spot welding in vertical position (Ukraine)

1.38. M.V. Matvienko, G.V. Ermolaev, V.V. Kvasnitsky. Influence of slipping of dissimilar material surfaces being joined on the stress-strain state in vacuum diffusion welding with thermal cycling (Ukraine)

1.39. P. Mayr, M. Kusch, L. Ebert, F. Podlesak. Influence of plasma transfer arc welding with pulsed process gas feeding on welding metallurgy of cobalt based hardfacing alloys (Germany)

1.40. S.I. Moravetsky, A.K. Tsaryuk, V.Yu. Skulsky. Certification of technology of welding combined rotors from steels 25Kh2NMFA + 20Kh3MVFA (EI415) for steam turbines (Ukraine)

1.41. N.P. Nesterenko, A.N. Galchun, V.Yu. Kondratenko, A.G. Skok. On effectiveness of application of pneumatically driven machine for butt welding of up to 400 mm diameter pipes from crystal-amorphous polymers (Ukraine)

1.42. N.P. Nesterenko, S.M. Dyachenko, I.K. Senchenkov. Technology and equipment for ultrasonic welding of heat-resistant composite materials applied in automotive and aircraft construction (Ukraine)

1.43. N.P. Nesterenko, N.G. Korab, A.N. Galchun. Experimental-theoretical investigation of laser welding of thin polyethylene films (Ukraine)

1.44. N.P. Nesterenko, E.A. Mineev. Features of welding pipes from unplasticized polyvinylchloride (Ukraine)

1.45. B.E. Paton, Yu.N. Saraev, V.A. Lebedev. Prospects for development and practical application of pulsed welding and surfacing technologies to improve operating reliability of critical metal structures (Ukraine, Russia)

1.46. B.E. Paton, K.A. Yushchenko, I.I. Lychko, S.A. Suprun, S.M. Kozulin, A.A. Klimenko. Investigation of the processes of formation of welded joint metal in electroslag welding with wire electrodes (Ukraine)

1.47. I.V. Pentegov, V.N. Sidorets, S.V. Rymar, A.M. Zhernosekov. Influence of modern arc power sources on the mains (Ukraine)

1.48. A.S. Pismennii, A.A. Pismennii, A.S. Prokofjev, R.S. Gubatyuk. Investigation and development of experimental technology and equipment for heat treatment of welds of railway rails (Ukraine)

1.49. A.S. Pismennii, V.V. Polukhin, Vl.V. Polukhin, R.S. Gubatyuk. Experimental technologies and equipment for seam welding and braze-welding of thin-walled pipes from high-strength steels by high-frequency currents (Ukraine)

1.50. V.B. Porokhonko, I.V. Protokovilov, A.T. Nazarchuk, D.A. Petrov, L.M. Babich. Electroslag welding of titanium alloys with pulsed electromagnetic impact (Ukraine)

1.51. H. Pokhmurska, B. Wielage, Ch.Rupprecht. Overview lecture about research trends for TS-processes (Germany)

1.52. I.K. Pokhodnya, A.V. Ignatenko, A.P. Paltsevich, V.S. Sinyuk. Hydrogen- induced cold cracks in welded joints of HSLA steels (Ukraine)

1.53. S.G. Psakhtje, K.A. Yushchenko, Yu.N. Saraev, Yu.N. Kakhovsky, V.P. Bezborodov. Establishing scientific fundamentals of development of multimodal welding consumables and pulsed technologies to produce permanent joints and fused coatings with multiscale structure for items operating in extreme north and arctic regions (Ukraine)

1.54. A.D. Razmyshlayev, M.V. Mironova, S.V. Yarmonov, P.A. Vydymysh. Improvement of effectiveness of processes of arc welding and surfacing under the impact of controlling magnetic fields (Ukraine)

1.55. M.K. Reznichenko, M.K. Kalin, K.O. Izotova. New methods of cold welding of cast iron by low-carbon materials (Ukraine)

1.56. A.P. Semyonov, I.V. Krivtsun, V.F. Demchenko. Simulation of the processes of melting and fusion of electrode metal in consumable electrode welding (Ukraine)

1.57. A.G. Sineok, A.M. Gerasimenko, V.D. Ryabokon, K.V. Ryabtsev, V.V. Brichak, S.N. Tolstyi. Modern welding technologies at enlargement and mounting of the arch metal structures of Podol bridge in Kiev (Ukraine)

1.58. A.G. Sineok, A.M. Gerasimenko, V.D. Ryabokon, K.V. Ryabtsev, A.A. Gotsulyak. Development of technologies of welding weather-resistant rolled stock of strength classes 355–500 MPa (Ukraine, Poland)

1.59. T.G. Skuba, V.A. Kolyada, V.V. Dolinenko, E.V. Shapovalov Development of simulation model of robotic multipass MIG/MAG welding for experimental investigations of the influence of schematics and modes of making the welds on stress-strain states (Ukraine)

1.60. E.G. Ternovoj, V.F. Shulym, Yu.N. Lankin. Repair of fragments of the case of internatonal space station with application of electron beam welding (Ukraine)

1.61. A.I. Ustinov, T.V. Melnichenko, Yu.V. Falchenko, L.V. Petrushinets. Electron beam methods to produce nanostructured foils and their application in welding of difficult-to-weld materials (Ukraine)

1.62. A.I. Ustinov, V.A. Telichko, S.A. Demchenkov, C. Bruckmueller, A. Hancic. EB PVD technology of producing functional quasicrystalline coatings and their properties (Ukraine, Austria, Slovenia)

1.63. G.K. Kharchenko, M.N. Rudenko, O.O. Novomlinets, M.O. Khomenko. Generation of electric potential on the surface of metal samples at self-propagating high-temperature synthesis in nanolayered foils (Ukraine)

1.64. V.F. Khorunov, S.V. Maksimova. Vacuum brazing of multilayer thinwalled structures (Ukraine).

1.65. V.F. Khorunov, Khorunov, S.V. Maksimova, V.V. Myasoed. Formation of brazed joints based on Ni3Al (Ukraine)

1.66. A.K. Tsaryuk, V.D. Ivanenko, N.I. Dunaevskaya. Repair technology for extension of service life of boilers of operating HPP power units (Ukraine)

1.67. A.K. Tsaryuk, O.G. Kasatkin, V.Yu. Skulsky, S.I. Moravetsky, A.R. Gavrik. Technology of welding from one side clad pipelines of primary coolant circuit of NPP power units (Ukraine)

1.68. D.A. Chinakhov. Investigation of the influence of shielding gas jet on heat distribution in the consumable electrode welding zone (Russia)

1.69. D.A. Chinakhov, A.V. Zuev. Consumable electrode welding with double- jet gas shielding (Russia)

1.70. V.A. Shapka. Selection of the structure of driving genereator for operation of HFMP actuator (Ukraine)

1.71. V.D. Shelyagin, V.Yu. Khaskin, A.G. Lukashenko. Laser welding of expansion bellows (Ukraine)

1.72. M.A. Sholokhov, A.M. Fiveiskii, D.S. Buzorina. Investigation of the influence of technological parameters on formation of near-wall bead in gas-shielded multipass welding (Russia)

1.73. M.A. Sholokhov, A.M. Fiveiskii, A.Yu. Melnikov. Twin-arc welding and its practical implementation (Russia)

1.74. K.A. Yushchenko, I.S. Gakh, B.A. Zaderiy, A.V. Zvyaginsteva, O.P. Karasevskaya. Metallurgical and technological issues of welding and repair of single-crystal blades from high-strength nickel alloys (Ukraine)

1.75. K.A. Yushchenko, T.N. Kushnareva, V.E. Mazurak. Results of investigation of producing high-temperature nickel alloy joints by reaction-diffusion process (Ukraine)

2. STRENGTH OF WELDED JOINTS AND STRUCTURES, THEORETICAL AND EXPERIMENTAL INVESTIGATIONS OF STRESS-STRAIN STATES AND THEIR CONTROL

( Click to view / hide the list of reports)

2.1. A.I. Balytsky, Ye. Novatsky, I.F. Kostyuk, O.B. Vus, O.S. Skolozdra. Performance of high-nitrogen steels and their welded joints at long service in hydrogen (Poland, Ukraine)

2.2. I.A. Boyko, A.G. Grin, V.K. Lysak. Methods of determination of hot hardness of metal (Ukraine)

2.3. I.A. Galtsov, A.V. Kalenskaya, S.A. Tkachenko, A.N. Tkachenko. Control of residual welding stresses during welding of clad steel 09G2S + 08Kh18N10T (Ukraine)

2.4. O.R. Gachkevich, V.I. Astashkin, T.V. Kozakevich, A. Ravska-Skotniczni. Phase composition and residual stresses in thin steel plates during preheating using moving heat sources (Ukraine, Poland)

2.5. L.S. Denisov. Investigation of formation of defectiveness of welded joints (Belarus)

2.6. A. Dzyubik. Residual strength of main pipelines of high-strength steels (Ukraine)

2.7. V.V. Dmitrik, S.N. Bartash. Towards the mechanism of ageing of welded joints of steam pipelines (Ukraine)

2.8. V.V. Dmitrik, T.A. Sirenko. Mechanism of degradation of metal of welded joints of steam pipelines (Ukraine)

2.9. A.B. Dub, V.A. Durynin, A.N. Razygraev, N.P. Razygraev, L.M. Lobanov, O.V. Makhnenko. Ultrasonic testing, damageability and serviceability of elements of collector welding to steam generator at NPP with WWER?1000 (Russia, Ukraine)

2.10. P.V. Zankovets, V.K. Sheleg. Influence of dominating factors on formation of welded joints under the conditions of single and small-scale welding manufacturing (Belarus)

2.11. V.V. Kvasnitsky, I.A. Kolesar, V.F. Kvasnitsky, G.V. Ermolaev, A.V. Labartkava. Investigation of influence of rigidity and strength of interlayer on stress-strain state at loading of welded and brazed components by axial load (Ukraine)

2.12. J. Kleiman, Yu. Kudryavtsev . Application of ultrasonic peening in industry (Canada)

2.13. I.N. Klochkov, I.V. Berezin, O.V. Berezin. Increase of life of welded joints of thin-sheet aluminium alloys using high-frequency mechanical peening (Ukraine)

2.14. V.V. Knysh, S.A. Solovey, A.Z. Kuzmenko. Increase of cyclic life of welded joints of in-service metal structures using high-frequency mechanical peening (Ukraine)

2.15. E.V. Kolomiytsev. Improvement of service life of changeable equipment and welded structures of open-hearth shop (Ukraine)

2.16. E.V. Kolomiytsev. Fatigue and corrosion-fatigue strength and life of welded joints of steel 12Kh18N10T (Ukraine)

2.17. E.V. Kolomiytsev, A.N. Serenko. Increase of life and fatigue strength of welded structures by surface plastic treatment (Ukraine)

2.18. O.V. Kolot, S.O. Tkachenko, A.M. Tkachenko. Vibro-treatment as a reserve of quality improvement of metal structures (Ukraine)

2.19. D.Yu. Kuzmenko, V.G. Prosnitsky, O.V. Makhnenko, Yu.V. Demchenko. All-welded wheels of agglomeration blowers N7500, N6500 (Ukraine)

2.20. R.M. Kushnir, B.D. Drobenko. Assessment of stressed state and service life of elements of 200 MW power units (Ukraine)

2.21. L.M. Lobanov, V.A. Pivtorak, V.V. Savitsky, G.I. Tkachuk, V.V Lysak. Determination of residual stresses in welded T-joints of titanium alloy VT-20 applying method of electron speckle-interferometry (Ukraine)

2.22. L.I. Markashova, O.S. Kushnareva. Investigation of correlation of structure with mechanical properties of welded joints of aluminium-lithium alloy (Ukraine)

2.23. L.I. Markashova, V.D. Poznyakov, E.N. Berdnikova, T.A. Alekseenko, A.A. Maksimenko. Welded joints of high-strength steels under service conditions (Ukraine)

2.24. L.I. Markashova, V.D. Shelyagin, V.Yu. Khaskin, O.S. Kushnareva, A.V. Bernatsky. Structure and mechanical properties of structural steel surface layers forming under conditions of laser and laser-plasma alloying (Ukraine)

2.25. V.I. Makhnenko, E.A. Velikoivanenko, G.F. Rozynka, N.I. Pivtorak. Mathematic models of tough fracture of welded structures based on mechanism of pore formation (Ukraine)

2.26. O.V. Makhnenko, I.V. Mirzov. Investigation of stress-strain state of inner-body devices on the example of baffle plate of reactor WWER-1000 (Ukraine)

2.27. S.V. Medvedev, K.A. Klimov. Prediction supercomputer modeling of processes of fracture of critical welded structures (Belarus)

2.28. S.V. Medvedev, O.P. Chizh. Constructive-technological designing of welded structures with application of supercomputer facilities of national grid-NETWORK (Belarus)

2.29. A.S. Milenin. Methodological bases of planning of repair of main pipelines without service interruption (Ukraine)

2.30. V.V. Mutas, M.A. Netrebsky, M.D. Rabkina. Method of assessment of stress-strain state of cylindrical structures, operating under internal pressure, with local surface defects (Ukraine)

2.31. Z.T. Nazarchuk, V.P. Skalsky. Methodological bases of identification of mechanisms of fracture of aluminium alloy welded joints by acoustic emission parameters (Ukraine)

2.32. Z.T. Nazarchuk, V.P. Skalsky, O.M. Stankevich, I.M. Lyasota. Identification of fracture mechanisms of welded joints of alloy 1201-T by parameters of acoustic emission signals (Ukraine)

2.33. V.A. Nekhotyashchiy, A.L. Palienko, A.A. Perepichaj, M.D. Rabkina. Prediction of safe service of pressure vessels with account for magnetic inhomogeneity of metal (Ukraine)

2.34. G.M. Nikiforchin, O.T. Tsirulnik, O.I. Zvirko, M.I. Gredil, V.A. Voloshin. Peculiarities of corrosion-hydrogen degradation of properties of welded joints of main gas pipelines (Ukraine)

2.35. A.I. Panfilov. Application of bimetal sheets SWIP for protection of technological equipment (Ukraine)

2.36. F.I. Panteleenko, A.S. Snarsky. Ageing of welded critical structures and search for method of nondestructive assessment of metal resistance to impact action (Ukraine)

2.37. M.I. Podgurskiy, B.P. Tatarin, I.M. Podgurskyi. Modeling of initiation and propagation of fatigue surface cracks in welded joints (Ukraine)

2.38. V.D. Poznyakov, S.L. Zhdanov, A.A. Maksimenko. New structural steels for welded building metal structures (Ukraine)

2.39. M.V. Radchenko, B.I. Mandrov. Improvement of service life of containers by application of welded shells of polymeric materials (Russia)

2.40. V.A. Royanov, P.V. Korostashevsky. Investigation of formula of end edge bending of sheet panels by accounting for empiric coefficient of stickout length and sheet thickness (Ukraine)

2.41. A.V. Sviridov, A.G. Grin. Investigation of mechanical properties of welded joints on copper base (Ukraine)

2.42. M.S. Khoma. Corrosion-mechanical fracture of pipe steels with welded joints in hydrogen sulphide environments (Ukraine)

2.43. K.A.Yushchenko, T.N. Kushnareva, V.A. Mazurak. Results of investigations of producing joints of heat-resistant nickel alloys by reaction-diffusion method (Ukraine)

2.44. K.A. Yushchenko, V.S. Savchenko, A.V. Zvyagintseva, N.O. Chervyakov, V.N. Tkach. Assessment of crystallographic anisotropy of elastic properties of weld metal of nickel alloys by using nanoindentation (Ukraine)

2.2. I.A. Boyko, A.G. Grin, V.K. Lysak. Methods of determination of hot hardness of metal (Ukraine)

2.3. I.A. Galtsov, A.V. Kalenskaya, S.A. Tkachenko, A.N. Tkachenko. Control of residual welding stresses during welding of clad steel 09G2S + 08Kh18N10T (Ukraine)

2.4. O.R. Gachkevich, V.I. Astashkin, T.V. Kozakevich, A. Ravska-Skotniczni. Phase composition and residual stresses in thin steel plates during preheating using moving heat sources (Ukraine, Poland)

2.5. L.S. Denisov. Investigation of formation of defectiveness of welded joints (Belarus)

2.6. A. Dzyubik. Residual strength of main pipelines of high-strength steels (Ukraine)

2.7. V.V. Dmitrik, S.N. Bartash. Towards the mechanism of ageing of welded joints of steam pipelines (Ukraine)

2.8. V.V. Dmitrik, T.A. Sirenko. Mechanism of degradation of metal of welded joints of steam pipelines (Ukraine)

2.9. A.B. Dub, V.A. Durynin, A.N. Razygraev, N.P. Razygraev, L.M. Lobanov, O.V. Makhnenko. Ultrasonic testing, damageability and serviceability of elements of collector welding to steam generator at NPP with WWER?1000 (Russia, Ukraine)

2.10. P.V. Zankovets, V.K. Sheleg. Influence of dominating factors on formation of welded joints under the conditions of single and small-scale welding manufacturing (Belarus)

2.11. V.V. Kvasnitsky, I.A. Kolesar, V.F. Kvasnitsky, G.V. Ermolaev, A.V. Labartkava. Investigation of influence of rigidity and strength of interlayer on stress-strain state at loading of welded and brazed components by axial load (Ukraine)

2.12. J. Kleiman, Yu. Kudryavtsev . Application of ultrasonic peening in industry (Canada)

2.13. I.N. Klochkov, I.V. Berezin, O.V. Berezin. Increase of life of welded joints of thin-sheet aluminium alloys using high-frequency mechanical peening (Ukraine)

2.14. V.V. Knysh, S.A. Solovey, A.Z. Kuzmenko. Increase of cyclic life of welded joints of in-service metal structures using high-frequency mechanical peening (Ukraine)

2.15. E.V. Kolomiytsev. Improvement of service life of changeable equipment and welded structures of open-hearth shop (Ukraine)

2.16. E.V. Kolomiytsev. Fatigue and corrosion-fatigue strength and life of welded joints of steel 12Kh18N10T (Ukraine)

2.17. E.V. Kolomiytsev, A.N. Serenko. Increase of life and fatigue strength of welded structures by surface plastic treatment (Ukraine)

2.18. O.V. Kolot, S.O. Tkachenko, A.M. Tkachenko. Vibro-treatment as a reserve of quality improvement of metal structures (Ukraine)

2.19. D.Yu. Kuzmenko, V.G. Prosnitsky, O.V. Makhnenko, Yu.V. Demchenko. All-welded wheels of agglomeration blowers N7500, N6500 (Ukraine)

2.20. R.M. Kushnir, B.D. Drobenko. Assessment of stressed state and service life of elements of 200 MW power units (Ukraine)

2.21. L.M. Lobanov, V.A. Pivtorak, V.V. Savitsky, G.I. Tkachuk, V.V Lysak. Determination of residual stresses in welded T-joints of titanium alloy VT-20 applying method of electron speckle-interferometry (Ukraine)

2.22. L.I. Markashova, O.S. Kushnareva. Investigation of correlation of structure with mechanical properties of welded joints of aluminium-lithium alloy (Ukraine)

2.23. L.I. Markashova, V.D. Poznyakov, E.N. Berdnikova, T.A. Alekseenko, A.A. Maksimenko. Welded joints of high-strength steels under service conditions (Ukraine)

2.24. L.I. Markashova, V.D. Shelyagin, V.Yu. Khaskin, O.S. Kushnareva, A.V. Bernatsky. Structure and mechanical properties of structural steel surface layers forming under conditions of laser and laser-plasma alloying (Ukraine)

2.25. V.I. Makhnenko, E.A. Velikoivanenko, G.F. Rozynka, N.I. Pivtorak. Mathematic models of tough fracture of welded structures based on mechanism of pore formation (Ukraine)

2.26. O.V. Makhnenko, I.V. Mirzov. Investigation of stress-strain state of inner-body devices on the example of baffle plate of reactor WWER-1000 (Ukraine)

2.27. S.V. Medvedev, K.A. Klimov. Prediction supercomputer modeling of processes of fracture of critical welded structures (Belarus)

2.28. S.V. Medvedev, O.P. Chizh. Constructive-technological designing of welded structures with application of supercomputer facilities of national grid-NETWORK (Belarus)

2.29. A.S. Milenin. Methodological bases of planning of repair of main pipelines without service interruption (Ukraine)

2.30. V.V. Mutas, M.A. Netrebsky, M.D. Rabkina. Method of assessment of stress-strain state of cylindrical structures, operating under internal pressure, with local surface defects (Ukraine)

2.31. Z.T. Nazarchuk, V.P. Skalsky. Methodological bases of identification of mechanisms of fracture of aluminium alloy welded joints by acoustic emission parameters (Ukraine)

2.32. Z.T. Nazarchuk, V.P. Skalsky, O.M. Stankevich, I.M. Lyasota. Identification of fracture mechanisms of welded joints of alloy 1201-T by parameters of acoustic emission signals (Ukraine)

2.33. V.A. Nekhotyashchiy, A.L. Palienko, A.A. Perepichaj, M.D. Rabkina. Prediction of safe service of pressure vessels with account for magnetic inhomogeneity of metal (Ukraine)

2.34. G.M. Nikiforchin, O.T. Tsirulnik, O.I. Zvirko, M.I. Gredil, V.A. Voloshin. Peculiarities of corrosion-hydrogen degradation of properties of welded joints of main gas pipelines (Ukraine)

2.35. A.I. Panfilov. Application of bimetal sheets SWIP for protection of technological equipment (Ukraine)

2.36. F.I. Panteleenko, A.S. Snarsky. Ageing of welded critical structures and search for method of nondestructive assessment of metal resistance to impact action (Ukraine)

2.37. M.I. Podgurskiy, B.P. Tatarin, I.M. Podgurskyi. Modeling of initiation and propagation of fatigue surface cracks in welded joints (Ukraine)

2.38. V.D. Poznyakov, S.L. Zhdanov, A.A. Maksimenko. New structural steels for welded building metal structures (Ukraine)

2.39. M.V. Radchenko, B.I. Mandrov. Improvement of service life of containers by application of welded shells of polymeric materials (Russia)

2.40. V.A. Royanov, P.V. Korostashevsky. Investigation of formula of end edge bending of sheet panels by accounting for empiric coefficient of stickout length and sheet thickness (Ukraine)

2.41. A.V. Sviridov, A.G. Grin. Investigation of mechanical properties of welded joints on copper base (Ukraine)

2.42. M.S. Khoma. Corrosion-mechanical fracture of pipe steels with welded joints in hydrogen sulphide environments (Ukraine)

2.43. K.A.Yushchenko, T.N. Kushnareva, V.A. Mazurak. Results of investigations of producing joints of heat-resistant nickel alloys by reaction-diffusion method (Ukraine)

2.44. K.A. Yushchenko, V.S. Savchenko, A.V. Zvyagintseva, N.O. Chervyakov, V.N. Tkach. Assessment of crystallographic anisotropy of elastic properties of weld metal of nickel alloys by using nanoindentation (Ukraine)

3. NONDESTRUCTIVE TESTING AND TECHNICAL DIAGNOSTICS

( Click to view / hide the list of reports)

3.1. E.A. Davydov, A.L. Shekero, P.S. Yukhimets, M. Mihovski, A. Alexsiev, G. Mirchev. Application of current ultrasonic testing technology LRUT for detection of corrosion damages of metal of main pipelines (Ukraine, Bulgaria)

3.2. M.N. Karmanov, V.A. Shalaev. Modular systems of digital radiation testing (Ukraine)

3.3. L.M. Lobanov, V.A. Pivtorak, I.V. Kiyanets, V.V. Savitskiy, E.M. Savitskaya. Non-destructive determination of diameters of nuggets of spot welded joints by electron shearography method using mechanical and thermal loading (Ukraine)

3.4. L.M. Lobanov, V.A. Pivtorak, V.A. Nekhotyashchiy, P.D. Krotenko, K.V. Shiyan. Prediction of failure pressure of pipes with corrosion defects using laser interferometry (Ukraine)

3.5. L.M. Lobanov, V.A. Pivtorak, E.M. Savitskaya, I.V. Kiyanets. Quality control of welded titanium panels from VT-20 alloy using electron shearography method (Ukraine)

3.6. A.Ya. Nedoseka, S.A. Nedoseka, M.A. Yaremenko, M.A. Ovsienko, L.F. Kharchenko. Acoustic-emission diagnostics of equipment of enterprises of power complex (Ukraine)

3.7. Yu.N. Posypayko. Developments of the E.O. Paton Electric Welding Institute in area of control of leak-proofness of welded joints (Ukraine)

3.8. M.S. Sorokin, A.A. Belov, V.A. Lebedev. System for automation and control of welding production ( Russia, Ukraine)

3.9. V.A. Troitsky, N.G. Belyi, V.N. Bukhenskiy, S.R. Mikhaylov. Fast digital X-ray-television system based on X-ray screens and CCD-cameras (Ukraine)

3.10. V.A. Troitsky, M.N. Karmanov, V.M. Gorbik. Diagnostic ultrasonic complexes «UNIVERSAL-1P» and «UNIVERSAL-2P» (Ukraine )

3.11. V.A. Troitsky, Yu.N. Posypayko. Complex non-destructive testing of welded tanks of large volume (Ukraine)

3.12. V.A. Troitsky, Yu.N. Posypayko, Yu.S. Agalidi, S.V. Levyi. Magnetooptical flaw detection of near-surface layers of ferromagnetic parts (Ukraine)

3.13. V.M. Uchanin. Eddy-current testing of welded joints (Ukraine)

3.14. E.V. Shapovalov, V.A. Kolyada. Development of updating diagnostic equipment for mobile and removable means of automated testing of geometry of railway track (Ukraine)

3.15. E.V. Shapovalov, R.M. Galagan, F.S. Klishchar, V.I. Zapara Experience of development of acoustic-emission system for testing of resistance spot welding (Ukraine)

3.16. S.A. Shchupak, N.V. Troitskaya, Yu.N. Posypayko, A.L. Shekero. New standards in area of non-destructive testing of welded joints (Ukraine)

3.2. M.N. Karmanov, V.A. Shalaev. Modular systems of digital radiation testing (Ukraine)

3.3. L.M. Lobanov, V.A. Pivtorak, I.V. Kiyanets, V.V. Savitskiy, E.M. Savitskaya. Non-destructive determination of diameters of nuggets of spot welded joints by electron shearography method using mechanical and thermal loading (Ukraine)

3.4. L.M. Lobanov, V.A. Pivtorak, V.A. Nekhotyashchiy, P.D. Krotenko, K.V. Shiyan. Prediction of failure pressure of pipes with corrosion defects using laser interferometry (Ukraine)

3.5. L.M. Lobanov, V.A. Pivtorak, E.M. Savitskaya, I.V. Kiyanets. Quality control of welded titanium panels from VT-20 alloy using electron shearography method (Ukraine)

3.6. A.Ya. Nedoseka, S.A. Nedoseka, M.A. Yaremenko, M.A. Ovsienko, L.F. Kharchenko. Acoustic-emission diagnostics of equipment of enterprises of power complex (Ukraine)

3.7. Yu.N. Posypayko. Developments of the E.O. Paton Electric Welding Institute in area of control of leak-proofness of welded joints (Ukraine)

3.8. M.S. Sorokin, A.A. Belov, V.A. Lebedev. System for automation and control of welding production ( Russia, Ukraine)

3.9. V.A. Troitsky, N.G. Belyi, V.N. Bukhenskiy, S.R. Mikhaylov. Fast digital X-ray-television system based on X-ray screens and CCD-cameras (Ukraine)

3.10. V.A. Troitsky, M.N. Karmanov, V.M. Gorbik. Diagnostic ultrasonic complexes «UNIVERSAL-1P» and «UNIVERSAL-2P» (Ukraine )

3.11. V.A. Troitsky, Yu.N. Posypayko. Complex non-destructive testing of welded tanks of large volume (Ukraine)

3.12. V.A. Troitsky, Yu.N. Posypayko, Yu.S. Agalidi, S.V. Levyi. Magnetooptical flaw detection of near-surface layers of ferromagnetic parts (Ukraine)

3.13. V.M. Uchanin. Eddy-current testing of welded joints (Ukraine)

3.14. E.V. Shapovalov, V.A. Kolyada. Development of updating diagnostic equipment for mobile and removable means of automated testing of geometry of railway track (Ukraine)

3.15. E.V. Shapovalov, R.M. Galagan, F.S. Klishchar, V.I. Zapara Experience of development of acoustic-emission system for testing of resistance spot welding (Ukraine)

3.16. S.A. Shchupak, N.V. Troitskaya, Yu.N. Posypayko, A.L. Shekero. New standards in area of non-destructive testing of welded joints (Ukraine)

4. SURFACE ENGINEERING

( Click to view / hide the list of reports)

4.1. M.A. Abralov. Boronizing of steel parts (Uzbekistan)

4.2. V.P. Bezborodov. Main regularities of structure formation and properties of transition zone of compositions with coatings after high-temperature effect (Russia)

4.3. E.V. Berezhnaya. Improvement of technology of electric contact hard-facing (Ukraine)

4.4. Yu.S. Borisov, E.A. Astakhov, Z.G. Ipatova, K.V. Yantsevich, A.I. Kildiy. Improvement of corrosion resistance of detonation coating of Fe-Cr-SiC composite powders, produced by mechanical-chemical synthesis (Ukraine)

4.5. Yu.S. Borisov, S.G. Voynarovich, A.N. Kislitsa, E.K. Kuzmich-Yanchuk. Microplasma spraying of biocompatible titanium coatings (Ukraine)

4.6. Yu.S. Borisov, I.A. Demyanov, N.V. Vigilyanskaya. Electric arc spraying of coatings with a pseudoalloy structure (Ukraine)

4.7. Yu.S. Borisov, M.V. Kuznetsov, A.V. Volos, V.G. Zadoya, V.V. Strelchuk, V.P. Kladko, V.F. Gorban. Magnetron sputtering of super-hard nanocomposite nc-TiC/a-C coatings (Ukraine)

4.8. Yu.S. Borisov, M.V. Kuznetsov, A.V. Volos, V.G. Zadoya, V.V. Strelchuk, V.P. Kladko, V.F. Gorban. Magnetron sputtering of nanocomposite CNx coating (Ukraine)

4.9. Yu.S. Borisov, A.P. Murashov, A.P. Grishchenko. Development and investigation of effectiveness of system of shielding the plasma jet with sprayed material from interaction with environment (Ukraine)

4.10. Yu.S. Borisov, A.P. Murashov, A.P. Grishchenko, N.V. Vigilyanskaya. Investigation of heat-protective properties of gradient coatings (Ukraine).

4.11. Yu.S. Borisov, V.L. Rupchev, A.N. Burlachenko, A.Yu. Tunik. Composite powders Fe-Cr-SiC for thermal spraying, produced by MChS, structure and properties (Ukraine)

4.12. A.L. Borisova, A.N. Burlachenko, A.P. Grishchenko, Z.G. Ipatova, T.V. Tsymbalistaya, K.V. Yantsevich. Heat-protective and corrosion properties of plasma coatings of complexly-alloyed alloy on AlCu-Fe base, containing a quasi-crystalline phase (Ukraine)

4.13. O.G. Bykovsky, A.N. Lapteva. Thermal state and fraction composition of particles in plasma spraying with current-carrying wire (Ukraine)

4.14. S.G. Voinarovich, E.K. Kuzmich-Yanchuk, A.N. Kislitsa, S.N. Kalyuzhnyi, O.P. Masyuchok, V.Yu. Glukhovsky. Microplasma resistive coatings, produced of titanium dioxide, for application in electric heaters (Ukraine).

4.15. D.A. Volkov, A.D. Koshevoy Effect of roughness of part surface on adhesion strength in electric contact surfacing (Ukraine)

4.16. A.A. Gaivoronsky, A.V. Klapatyuk, A.S. Shishkevich, V.Ya. Gritsaj. Technology of surfacing restoration of wheel tires of high-speed passenger transport (Ukraine)

4.17. S.V. Dragan, Zh.G. Goloborodko, I.V. Simutenkov. Automatic submerged arc surfacing with transverse high-frequency oscillations of electrode (Ukraine)

4.18. O.M. Dubovoy, A.A. Karpechenko, M.M. Bobrov. Effect of electric pulses on structure and hardness of electric arc coatings (Ukraine)

4.19. A.I. Evdokimov, Yu.M. Kuskov. Assessment of operation of water-air injector under conditions of electroslag surfacing of high-carbon materials (Ukraine)

4.20. Yu.S. Korobov, M.A. Filippov, V.V. Legchilo, Yu.V. Khudorozhkova, V.S. Verkhorubov. Influence of metastable chromium austenite on the properties of materials deposited by surfacing and spraying (Russia)

4.21. Yu.S. Korobov, M.A. Filippov, S.V. Nevezhin, G.A. Rimer. High-temperature coatings from flux-cored wires (Russia)

4.22. A.M. Kostin, A.Yu. Butejko. Development of high-temperature wear-resistant material for strengthening of band flanges of GTE blades (Ukraine)

4.23. O.G. Kuzmenko, I.P. Lentyugov. Development of materials for wear-resistant surfacing using grinding wastes of high-speed steel (Ukraine)

4.24. E.K. Kuzmich-Yanchuk, Yu.S. Borisov, S.G. Voynarovich, A.N. Kislitsa, A.Yu. Tunik. Reactive laser-plasma spraying of coatings on titanium base in the medium of active gas mixture H2 + CH4 (Ukraine)

4.25. Yu.N. Lankin, I.A. Ryabtsev, Ya.P. Chernyak, V.G. Solovjev, V.F. Semikin, P.P. Osechkov, V.A. Zhdanov. Experimental investigations of electric condition parameters of automatic submerged arc, open arc and shielded-gas surfacing (Ukraine)

4.26. N.A. Makarenko. Development of slag system of flux-cored flattened wire for PLASMA-MIG surfacing of aluminium alloys (Ukraine)

4.27. L.I. Markashova, Yu.N. Tyurin, O.V. Kolisnichenko, M.L. Valevich, D.G. Bogachev. Structural-phase state of working surfaces of parts from high-strength cast iron after pulse-plasma treatment (Ukraine).

4.28. L.N. Orlov, A.A. Golyakevich. Restoration surfacing of metallurgical equipment components with flux-cored wires at «TM. VELTEK LTD» (Ukraine)

4.29. A.V. Paustovsky, Yu.G. Tkachenko, R.A. Alfintseva, S.N. Kirilenko, D.Z. Yurchenko. Development of electrode materials for electric spark strengthening and restoration of worn-out surfaces (Ukraine)

4.30. V.V. Peremitko. Improvement of service life of running gear parts of road machines (Ukraine)

4.31. E.F. Pereplyotchikov. Experience of application of plasma-powder surfacing in valves and engine manufacture (Ukraine)

4.32. S.G. Plis. Effect of surfacing conditions and diameter of flux-cored wire on characteristics of its melting (Ukraine)

4.33. V.A. Presnyakov. Improvement of method of electric contact surfacing by flux-cored wire and strip (Ukraine)

4.34. V.P. Prilutsky, S.L. Shvab, I.A. Radkevich, S.V. Akhonin, S.L. Antonyuk. Restoration of properties of worn-out surface of airplane elements of titanium alloy VT22 by using the argon-arc surfacing (Ukraine)

4.35. V.G. Radchenko, M.V. Radchenko, Yu.O. Shevtsov, T.B. Radchenko. Development of technology of supersonic gas-powder surfacing for solution of problem of wear of parts of machines and mechanisms (Russia)

4.36. I.K. Senchenkov, I.A. Ryabtsev, O.P. Chervinko, I.I. Ryabtsev, A.A. Babinets. Calculated-experimental method of assessment of life of surfaced parts operating under conditions of cyclic thermal and mechanical loads (Ukraine)

4.37. E.V. Sukhovaya. Composite materials for furnace method of surfacing (Ukraine)

4.38. O.M. Shabliy, Ch.V. Pulka, V.Ya. Gavrilyuk, V.S. Senchishin, V.Ya. Grusha. New technological processes of induction surfacing of thin shaped discs (Ukraine)

4.2. V.P. Bezborodov. Main regularities of structure formation and properties of transition zone of compositions with coatings after high-temperature effect (Russia)

4.3. E.V. Berezhnaya. Improvement of technology of electric contact hard-facing (Ukraine)

4.4. Yu.S. Borisov, E.A. Astakhov, Z.G. Ipatova, K.V. Yantsevich, A.I. Kildiy. Improvement of corrosion resistance of detonation coating of Fe-Cr-SiC composite powders, produced by mechanical-chemical synthesis (Ukraine)

4.5. Yu.S. Borisov, S.G. Voynarovich, A.N. Kislitsa, E.K. Kuzmich-Yanchuk. Microplasma spraying of biocompatible titanium coatings (Ukraine)

4.6. Yu.S. Borisov, I.A. Demyanov, N.V. Vigilyanskaya. Electric arc spraying of coatings with a pseudoalloy structure (Ukraine)

4.7. Yu.S. Borisov, M.V. Kuznetsov, A.V. Volos, V.G. Zadoya, V.V. Strelchuk, V.P. Kladko, V.F. Gorban. Magnetron sputtering of super-hard nanocomposite nc-TiC/a-C coatings (Ukraine)

4.8. Yu.S. Borisov, M.V. Kuznetsov, A.V. Volos, V.G. Zadoya, V.V. Strelchuk, V.P. Kladko, V.F. Gorban. Magnetron sputtering of nanocomposite CNx coating (Ukraine)

4.9. Yu.S. Borisov, A.P. Murashov, A.P. Grishchenko. Development and investigation of effectiveness of system of shielding the plasma jet with sprayed material from interaction with environment (Ukraine)

4.10. Yu.S. Borisov, A.P. Murashov, A.P. Grishchenko, N.V. Vigilyanskaya. Investigation of heat-protective properties of gradient coatings (Ukraine).

4.11. Yu.S. Borisov, V.L. Rupchev, A.N. Burlachenko, A.Yu. Tunik. Composite powders Fe-Cr-SiC for thermal spraying, produced by MChS, structure and properties (Ukraine)

4.12. A.L. Borisova, A.N. Burlachenko, A.P. Grishchenko, Z.G. Ipatova, T.V. Tsymbalistaya, K.V. Yantsevich. Heat-protective and corrosion properties of plasma coatings of complexly-alloyed alloy on AlCu-Fe base, containing a quasi-crystalline phase (Ukraine)

4.13. O.G. Bykovsky, A.N. Lapteva. Thermal state and fraction composition of particles in plasma spraying with current-carrying wire (Ukraine)

4.14. S.G. Voinarovich, E.K. Kuzmich-Yanchuk, A.N. Kislitsa, S.N. Kalyuzhnyi, O.P. Masyuchok, V.Yu. Glukhovsky. Microplasma resistive coatings, produced of titanium dioxide, for application in electric heaters (Ukraine).

4.15. D.A. Volkov, A.D. Koshevoy Effect of roughness of part surface on adhesion strength in electric contact surfacing (Ukraine)

4.16. A.A. Gaivoronsky, A.V. Klapatyuk, A.S. Shishkevich, V.Ya. Gritsaj. Technology of surfacing restoration of wheel tires of high-speed passenger transport (Ukraine)

4.17. S.V. Dragan, Zh.G. Goloborodko, I.V. Simutenkov. Automatic submerged arc surfacing with transverse high-frequency oscillations of electrode (Ukraine)

4.18. O.M. Dubovoy, A.A. Karpechenko, M.M. Bobrov. Effect of electric pulses on structure and hardness of electric arc coatings (Ukraine)

4.19. A.I. Evdokimov, Yu.M. Kuskov. Assessment of operation of water-air injector under conditions of electroslag surfacing of high-carbon materials (Ukraine)

4.20. Yu.S. Korobov, M.A. Filippov, V.V. Legchilo, Yu.V. Khudorozhkova, V.S. Verkhorubov. Influence of metastable chromium austenite on the properties of materials deposited by surfacing and spraying (Russia)

4.21. Yu.S. Korobov, M.A. Filippov, S.V. Nevezhin, G.A. Rimer. High-temperature coatings from flux-cored wires (Russia)

4.22. A.M. Kostin, A.Yu. Butejko. Development of high-temperature wear-resistant material for strengthening of band flanges of GTE blades (Ukraine)

4.23. O.G. Kuzmenko, I.P. Lentyugov. Development of materials for wear-resistant surfacing using grinding wastes of high-speed steel (Ukraine)

4.24. E.K. Kuzmich-Yanchuk, Yu.S. Borisov, S.G. Voynarovich, A.N. Kislitsa, A.Yu. Tunik. Reactive laser-plasma spraying of coatings on titanium base in the medium of active gas mixture H2 + CH4 (Ukraine)

4.25. Yu.N. Lankin, I.A. Ryabtsev, Ya.P. Chernyak, V.G. Solovjev, V.F. Semikin, P.P. Osechkov, V.A. Zhdanov. Experimental investigations of electric condition parameters of automatic submerged arc, open arc and shielded-gas surfacing (Ukraine)

4.26. N.A. Makarenko. Development of slag system of flux-cored flattened wire for PLASMA-MIG surfacing of aluminium alloys (Ukraine)

4.27. L.I. Markashova, Yu.N. Tyurin, O.V. Kolisnichenko, M.L. Valevich, D.G. Bogachev. Structural-phase state of working surfaces of parts from high-strength cast iron after pulse-plasma treatment (Ukraine).

4.28. L.N. Orlov, A.A. Golyakevich. Restoration surfacing of metallurgical equipment components with flux-cored wires at «TM. VELTEK LTD» (Ukraine)

4.29. A.V. Paustovsky, Yu.G. Tkachenko, R.A. Alfintseva, S.N. Kirilenko, D.Z. Yurchenko. Development of electrode materials for electric spark strengthening and restoration of worn-out surfaces (Ukraine)

4.30. V.V. Peremitko. Improvement of service life of running gear parts of road machines (Ukraine)

4.31. E.F. Pereplyotchikov. Experience of application of plasma-powder surfacing in valves and engine manufacture (Ukraine)

4.32. S.G. Plis. Effect of surfacing conditions and diameter of flux-cored wire on characteristics of its melting (Ukraine)

4.33. V.A. Presnyakov. Improvement of method of electric contact surfacing by flux-cored wire and strip (Ukraine)

4.34. V.P. Prilutsky, S.L. Shvab, I.A. Radkevich, S.V. Akhonin, S.L. Antonyuk. Restoration of properties of worn-out surface of airplane elements of titanium alloy VT22 by using the argon-arc surfacing (Ukraine)

4.35. V.G. Radchenko, M.V. Radchenko, Yu.O. Shevtsov, T.B. Radchenko. Development of technology of supersonic gas-powder surfacing for solution of problem of wear of parts of machines and mechanisms (Russia)

4.36. I.K. Senchenkov, I.A. Ryabtsev, O.P. Chervinko, I.I. Ryabtsev, A.A. Babinets. Calculated-experimental method of assessment of life of surfaced parts operating under conditions of cyclic thermal and mechanical loads (Ukraine)

4.37. E.V. Sukhovaya. Composite materials for furnace method of surfacing (Ukraine)

4.38. O.M. Shabliy, Ch.V. Pulka, V.Ya. Gavrilyuk, V.S. Senchishin, V.Ya. Grusha. New technological processes of induction surfacing of thin shaped discs (Ukraine)

5. SPECIAL ELECTROMETALLURGY

( Click to view / hide the list of reports)

5.1. S.V. Anakhov, Yu.A. Pykin, A.V. Matushkin. Environmental principles of designing of electric plasma equipment (Russia)

5.2. S.V. Akhonin, V.A. Berezos, V.D. Korniychuk, A.N. Pikulin, A.Yu. Severin. Electron-beam technologies of producing ingots from titanium-base alloys (Ukraine)

5.3. E.A. Asnis, N.V. Piskun, I.I. Statkevich, P.I. Baranskii, V.M. Babich. Nitrogen alloying of silicon crystals in process of their growing by electron beam crucibleless zone melting method (Ukraine)

5.4. E.A. Asnis, N.V. Piskun, I.I. Statkevich, P.I. Baranskii, V.M. Babich. Electron beam crucibleless zone melting of silicon using heat shield (Ukraine)

5.5. F.K. Biktagirov, N.V. Reyda, V.A. Shapovalov, V.M. Efimov, A.A. Selyutin, V.G. Padalka. Electroslag heating and hot-topping of discard of large ingots of 200-400 t mass (Ukraine)

5.6. F.K. Biktagirov, V.A. Shapovalov, A.V. Gnatushenko, I.P. Ignatov. Electroslag melting of non-compact waste of copper and aluminum alloys (Ukraine)

5.7. A. Vlasov. Intensification of electroslag processes (Ukraine)

5.8. V.P. Piptyuk, I.V. Krikent, S.E. Samokhvalov, I.N. Logozinskiy, V.A. Polyakov, S.V. Grekov. Estimation of value and effect of electromagnetic forces on pool stirring of ladle furnace unit of alternating current (Ukraine)